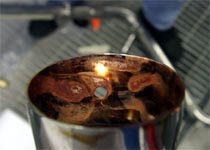

Figure 1.

Figure 2.

Figure 3.

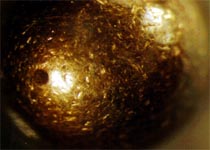

Figure 4.

Background

A problem occurred with localised rust spots being found in two purified water storage tanks. The rust spots appeared to be associated with isolated particulates on the floor of each tank near to the outlet drains. Enspec was requested to carry out an internal examination of the tanks in order to establish the nature and cause of the rusting.

Findings

The initial evidence indicated the rusting was associated with the particulates which were determined to be very small metal fragments. Some of the particulates had dissolved completely leaving a small mound of rust-coloured corrosion deposit, whereas in other areas, evidence of rusting was found beneath the particles.

During the course of the examination, it was noticeable that the rotary spray balls in both tanks were heavily tarnished as shown in figure 1. The spray ball from one of the tanks was subsequently removed for metallurgical analysis. The spray ball housing including the bearing race was constructed of an austenitic-ferritic alloy (SAF 2205), whereas the spray ball was made of an austenitic stainless steel (AISI 316L).

The initial examination revealed evidence of corrosion at a number of points with the most severely affected area being the inside surface of the fixed housing in the region of the retaining pin (figure 2). The inside and outside surfaces of the assembly were tarnished on the outside surface around the bearing and the upper section of the spray ball.

The inner surface of the housing exhibited colour banding just above the bearing contact surfaces which was indicative of excessive frictional heating. A macroscopic examination of the bearing contact surfaces revealed evidence of metal flaking associated with multi-directional cracking, being indicative of surface fatigue damage. The bearing contact surfaces also exhibited a generally worn appearance, together with a number of areas on both contact surfaces where localised denting had occurred

The macroscopic examination of the bearing balls revealed that they had been severely affected by surface fatigue damage, associated with what appeared to be very localised corrosion. The surface of the balls was quite rough with many surface marks and indentations being visible. Two of the balls showed evidence of localised friction damage as shown in figure 3. The straw brown colour of the balls suggested that they had been overheated at some stage.

A microscopic examination of the bearing races and the balls confirmed the presence of surface fatigue damage resulting in both surface and sub-surface cracking as shown in figure 4. The balls also showed signs of corrosion pitting and surface fatigue damage resulting in the detachment of very small flakes of metal

The cracking in the duplex alloy housing was generally very shallow and sub-surface, and it appeared to be orientated parallel to the surface. The majority of the cracking had propagated through the ferrite constituent of the duplex microstructure.

The results of the failure analysis showed that the corrosion around the securing pin resulted from a crevice corrosion mechanism between the mating surfaces of the feed pipe, the securing pin, and the upper fixed housing. The damage to the bearing surfaces had been caused by surface fatigue which resulted in cracking and flaking of the metal surface.

Key Points

- The analysis showed that the spray balls were the most likely source of the metal particles observed on the base of the tanks. There can be no doubt that had they remained in service, a point would have been reached where the balls would have disintegrated completely.

- The spray ball assembly would normally have been electropolished prior to assembly. There was however circumstantial evidence to suggest that the spray ball had been re-electropolished in the assembled condition which was probably the major contributory factor to the development of localised corrosion on the balls and the race.