Figure 1.

Figure 2.

Figure 3.

Background

After about two years in operation, the top header of a 5 tray semi-continuous deodoriser suffered a catastrophic failure. The damage to the tray was extensive with the top header separating into 8 pieces and the coils becoming completely entangled as shown in figure 1. The bottom header was comparatively undamaged.

The shell of the unit had also been severely damaged as the downward force of the explosion on the tray had ripped a hole in the shell as shown in figure 2.

The information from the process instrumentation showed no unusual features in the operation of the unit prior to the failure.

Findings

It is well known that the coils in SCD's often suffer from thermal fatigue cracking due to the thermal cycling that is inherent in their operation. Small cracks generally tend to cause steam leaks.

In the more serious cases such as this, the problem arises when there is a large crack such as the total failure of a header or coil. The sudden release of high pressure steam into the oil in the SCD, which is typically at 5 mbar, resulted in a violet reaction.

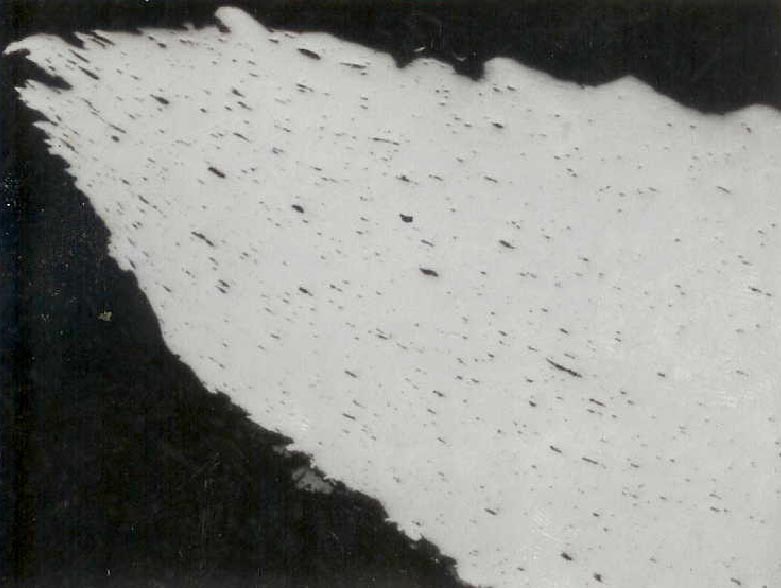

An examination of the fractured top header revealed the presence of fabrication defects that most likely initiated thermal fatigue cracking. The stainless steel header had failed by unstable ductile tearing once the initial fatigue crack had reached a critical size. A micrograph of the main fracture face in the failed header is shown in figure 3.

Ductile tearing, such as that encountered with this failure, occurred when the driving force for the crack extension originated from the stress in the total coil system. It was not the stress resulting from the internal pressure in the steam system. This is a fairly unusual failure mechanism for stainless steels. It is known that high stresses can be present in the steam heated coil systems because of their method of fabrication.

Key Point

- The rectangular design of the top header in this type of deodoriser is fairly common in older vessels. However, it was the way in which it had been poorly fabricated which was the primary factor responsible for the failure.

Back to Failure Case Histories