Figure 1.

Figure 2.

Figure 3.

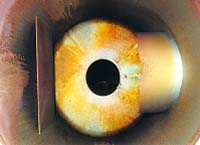

Figure 3.

Background

A failure occurred in a vacuum condenser vessel fitted with a venturi deflector plate, which became detached and subsequently blocked the outlet downpipe. This resulted in a build-up of condensate which overflowed and reversed through the horizontal venturi unit into the deodoriser vessel. The plate had become detached as a result of fatigue cracking which had developed along the full length of both the vertical fillet welds.

Discussions with the factory engineers revealed that there had been past corrosion problems with the two smaller condenser vessels and with the degasser. The corrosion in each case was located opposite the vapour inlet. One of the vessels had been replaced after about 12 years of service.

Findings

A subsequent visual examination of the main condenser vessel in an identical vessel at another factory, revealed evidence of corrosion both on the carbon steel section of the vessel and on the vapour inlet shroud, as shown in figures 1 and 2. The type of corrosion was typical of fatty acid attack. Low levels of fatty acids are present in the feedstock and would normally be 'stripped off' during the deodorisation process.

The deflector plate was found to contain two large cracks in the weld which connected it to the main shell (figure 3). The crack at the top of the plate measured 85mm and the lower crack measured 30mm. The cracking was located at the same point in the welds as the vessel which had failed earlier. Upon closer examination, the welds were found to contain pre-existing defects such as incomplete fusion and penetration which acted as stress concentrators for the development of fatigue cracks.

Back to Failure Case Histories