Figure 1.

Figure 2.

Figure 3.

Background

Failures in the filter mesh from a vertical pressure leaf filter unit were experienced in an edible oil factory. A typical filter unit shown in figure 1, is used to remove bleaching earth from the edible oil. The filter is designed to operate at 4.5 bar at a temperature of 85°C. The filter body is normally constructed of a Werkstoff type HII carbon steel with stainless steel filter leaves.

Findings

The examination revealed that the filtering system consisted of three layers of filtering elements. All of the elements were supplied in type 316 stainless steel. The elements showed signs of cracking in the individual wires as shown in figure 2, which resulted in inefficient filtering. This resulted in an unacceptable level of contamination of the edible oil.

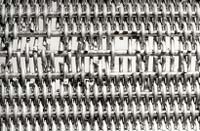

Subsequent metallurgical examination of the wires showed that they had failed as a result of stress corrosion cracking, which in the austenitic stainless steels such as 316, is usually associated with the presence of chlorides. The typical form of transgranular stress corrosion cracking is shown in figure 3.

Experience has shown that the majority of service failures with stress corrosion cracking with stainless steels take place above 60°C. In this particular case, no chlorides were meant to be present and the operating temperature was less than 60°C. However, the filters were cleaned with high pressure steam at a temperature above 60°C.

A review of the washdown procedure revealed that the filters were also cleaned with hot water under high pressure at a temperature above 60°C. It is most likely that the water contained chlorides which were responsible for the failure.

In general, there are only a limited number of environments that cause stress corrosion cracking in stainless steels and chlorides are the most commonly encountered cause.

Back to Failure Case Histories