Figure 1.

Figure 2.

Figure 3.

Background

After about two years of operation, an explosion occurred inside the combustion chamber of a high pressure boiler associated with a semi-continuous deodoriser. The explosion caused considerable damage to the burner assembly, the top cover plate, the adjacent condensate pipework and the electrical cabling. Figure 1 shows the damage to the top cover and surrounding equipment. The burner casing had suffered partial fragmentation. The design pressure of the boiler was 95 barg. The explosion occurred as the boiler was being shut down and was at a pressure of about 50 barg at the time of failure.

Findings

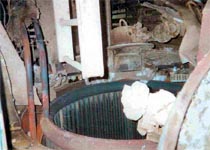

The failure investigation revealed that one of the riser tubes had failed at a point about one metre below the top header. The ruptured tube shown in figure 2 exhibited a creep type of failure. Further examination revealed signs of overheating resulting in longitudinal cracking in a number of other tubes. A metallurgical examination indicated that in certain areas, the tubes had been overheated resulting in a spheroidised microstructure. The carbides in the steel had changed from being lamellar in shape to spherical. The micrograph in figure 3 shows the outer surface of the tube at a magnification of 50x. There are numerous transgranular cracks penetrating an oxide layer measuring approximately 0.5mm thick. The evidence suggests that the burner was incorrectly set up resulting in excessive surface temperatures in the region of the flame.

Key Points

- Creep is a high temperature deformation process. It occurs at temperatures when the mechanical properties, especially the tensile properties, are not only determined by the magnitude of the applied load, but also by the time that the load is applied. Therefore, in the creep range the permissible design stress at a given temperature is time dependant. In order to prevent creep in boilers, it is normal to design the system such that the maximum service temperature of the tube wall is below the creep temperature.

- It is Enspec's experience that high pressure boilers, like all other types of boilers, eventually develop cracking usually resulting from a thermal fatigue mechanism, and therefore these boilers have a finite life. It is possible to extend the life of the boilers by implementing thorough examinations for evidence of both corrosion and cracking.

Enspec has carried inspections of a large number of these units and has therefore gained a great deal of knowledge about this particular type of boiler, and the service-related defects that can sometimes develop at specific points of the construction.

Back to Failure Case Histories