Figure 1.

Figure 2.

Figure 3.

Background

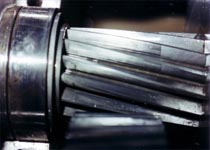

A new high pressure slurry pump had been installed over an existing concrete plinth, as part of an ongoing process revamping project (figure 1). Within the first few months of operation, a knocking sound developed in the gearbox which occurred at different speeds and gradually grew worse. The bearings showed signs of premature wear damage and were subsequently replaced on several occasions. There was also evidence of wear damage on the gear teeth as shown in figure 2.

A number of ideas were proposed, and in some cases implemented by both the factories' own personnel and the pump supplier. The pump supplier provided little onsite support where the problem persisted and the solutions served only to rectify the situation temporarily, as the knocking sound reappeared shortly after the bearings were replaced.

Findings

Enspec was requested to examine the installation as the downtime and cost of replacement bearings was beginning to be a major issue. An analysis of the vibration levels revealed that it was not a straightforward vibration problem resulting from imbalance or misalignment of the drive shaft.

The suppliers' technician suggested that the solution would be to replace the gearbox and to weld a 10 mm thick stiffening plate onto the base plate beneath the gearbox pedestal. No consideration had been given to the consequential excessive misalignment of the couplings that would have ensued had the proposal been put into action.

In conjunction with the factory maintenance personnel, Enspec assisted with the complete dismantling of the pump assembly and gearbox to determine its condition. The construction of the foundation was also examined to determine whether it was strong enough to support the base frame.

It was apparent that the construction of the foundation was unsuitable as a large cavity was found beneath the frame that allowed the baseplate to deflect during operation, resulting in a knocking noise from the gearbox at different speeds. Figure 3 shows the foundation block with evidence of liquid leaking from the cavity and defects in the concrete base. The decision was taken to fill the cavity with grout to provide a solid foundation for the baseplate.

The factory was subsequently able to operate the pump without any further problems and with the original gearbox in place.

Key Point

- The investigation showed that although the problem became manifest in the form of a knocking noise and premature wear of the gears, it was actually the construction of the foundation that was the primary cause of the problem. The construction of a solid foundation for any kind of rotating equipment is very important and needs careful consideration.

Back to Failure Case Histories