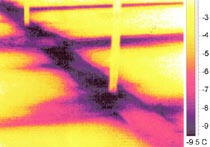

Figure 1.

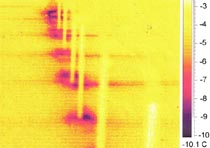

Figure 2.

Figure 3.

Background

A number of roof panels inside a cold store were found to be in a poor condition with evidence of icing between the joints. A local contractor had previously identified several roof panels which appeared to be in poor condition and therefore requiring replacement. As the roof was of a suspended design, there were obvious safety concerns and the potential for the loss of thermal energy through the joints. Enspec was requested to carry a thermographic survey of the building inside the roof cavity.

Findings

The initial survey revealed evidence of thermal bridging between the roof panels indicating the presence of an ice layer in the joint. This feature is clearly visible in figure 1. There was also visible evidence of ice and frost along some of the joints as shown in figure 2. The temperature of these joints was found to vary between -7°C and -11°C.

Another problem area was that of thermal bridging at the points where the hangar bars penetrated the roof panels. Figure 3 clearly shows this feature. The hangar rods were also beginning to show signs of corrosion at this point

Ice build-up was also observed on the exposed sections of pipework attached to the chiller units.

Key Points

- The main cause of the icing between the joints was found to be the level of condensation inside the roof space. There was very little airflow and insufficient venting. There was also no insulation on the underside of the outside roof panels which would make the situation worse, especially in the summertime when there would be higher fluctuating ambient temperatures.

- A recommendation was to introduce a temperature monitoring programme inside the roof cavity to monitor any fluctuations through the year. The results of the survey would provide valuable information when considering what type of insulation and ventilation system would be most appropriate.

Back to Failure Case Histories